VORTEX PRESSURE REGULATION STATION

PIPELINE (VPRS-PIPELINE)

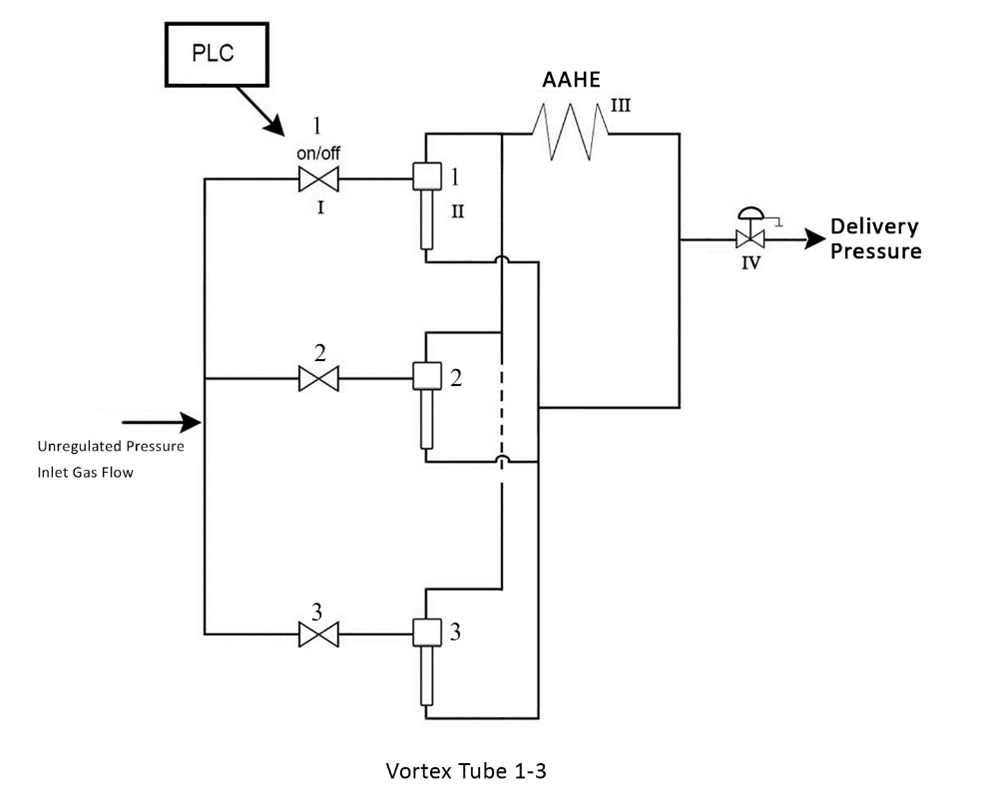

VPRS-Pipeline allows for complete elimination of high-pressure gas preheat and raises the pressure regulated gas temperature also without applying any external man-made energy. The technology has no limitation on Pipeline flow rate and the process initial and final/delivery pressures.

Overview

Operations

During VPRS operations, high pressure non pre-heated pipeline gas undergoes non-freeze pressure reduction and energy division in the self-heating vortex tube. The number of tubes in service is determined by the current pressure-regulated gas demand. The self-heating vortex tube's cold outlet, after getting warmed in an air-ambient heat exchanger (AAHE), is combined with the self-heating vortex tube's hot flow, upstream of a fine tune pressure regulator.

Depending on VPRS location it could be expedient at high ambient temperatures to direct some of the vortex tube cold outlet flow into a downstream pipe (bypass a AAHE) to achieve desired delivery gas temperature.

To increase the vortex tube cold outlet temperature, the actual free of charge vortex cooling load can be utilized (via glycol loop) for industrial applications in proximity to the gas pressure regulation facility.

Advantages

- NO lost gas

- NO carbon emissions

- NO maintenance

- GREEN technology

- FREE cooling load

Downloads