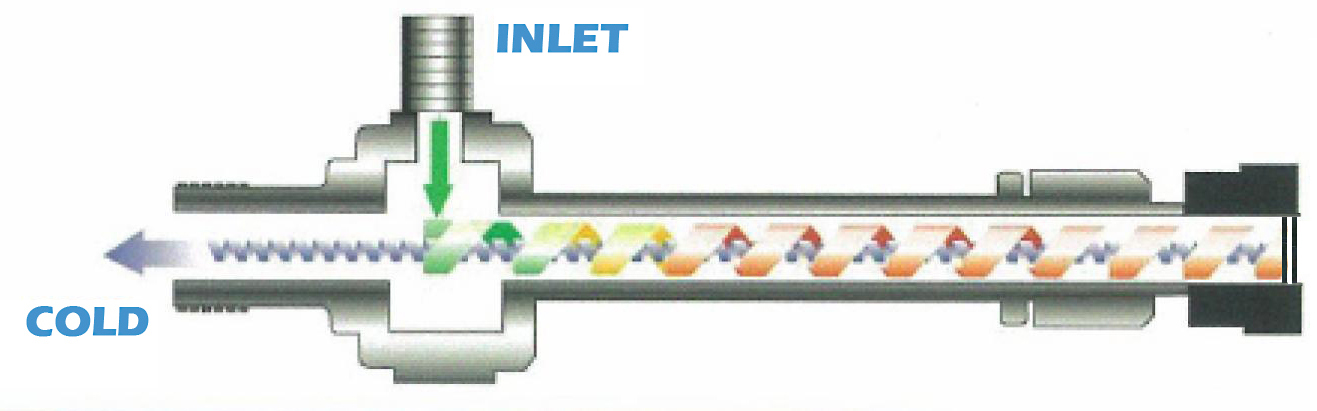

SINGLE PATH VORTEX TUBE TECHNOLOGY

UVI's Single Path Vortex Tube provides for the most intensive energy division

in the vortex flow resulting in the most effective spot heating.

How the Single Path Vortex Tube Works

In the Single Path Vortex Tube, high pressure gas expands in the unit’s tangential nozzle of a fixed size down to the delivery pressure. While in the VPR’s cylindrical body, the rotating low-pressure gas undergoes energy division (vortex phenomenon), forming two currents: cold and hot. The currents coexist in the VPR and exit the unit through a single discharge orifice. Prior to exiting the VPR, the hottest portion of the hot flow is internally directed to warm up the unit’s inlet nozzle (self-heating provision), thus protecting the inlet depressurized flow from a freeze up. The unique design provides for the most intensive energy division in the vortex flow, and accordingly, provides for the most effective spot heating. The vortex cold and the hot flows recombining at the VPR discharge negate their temperature differences. Therefore, the temperature of the combined flow at the VPR single discharge reflects only the Joule Thomson temperature drop in the expanded gas.

Applications

A wide range of applications exist for non freeze pressure reduction of non pre-heated gas with the subsequent temperature increase of the pressure regulated gas:

- Vortex Pilot Gas Heater

- Vortex Farm Tap Installations

- CNG Decompression

- CNG Compression Cooling

- Heavy Hydrocarbons Recovery from Wellhead Gas